IDS 2025

Meet DYNA-MESS at IDS 2025

You can find us in Hall 4.1 at Booth A-051

DYNA-MESS offers testing machines for chewing simulation and standard tests according to ISO 14801 on dental implants as well as for testing dental materials and orthodontic elements. Additionally DYNA-MESS has invented a machine for tests according to ASTM F543.

Wir sind DYNA-MESS. Prüfsysteme.

Products

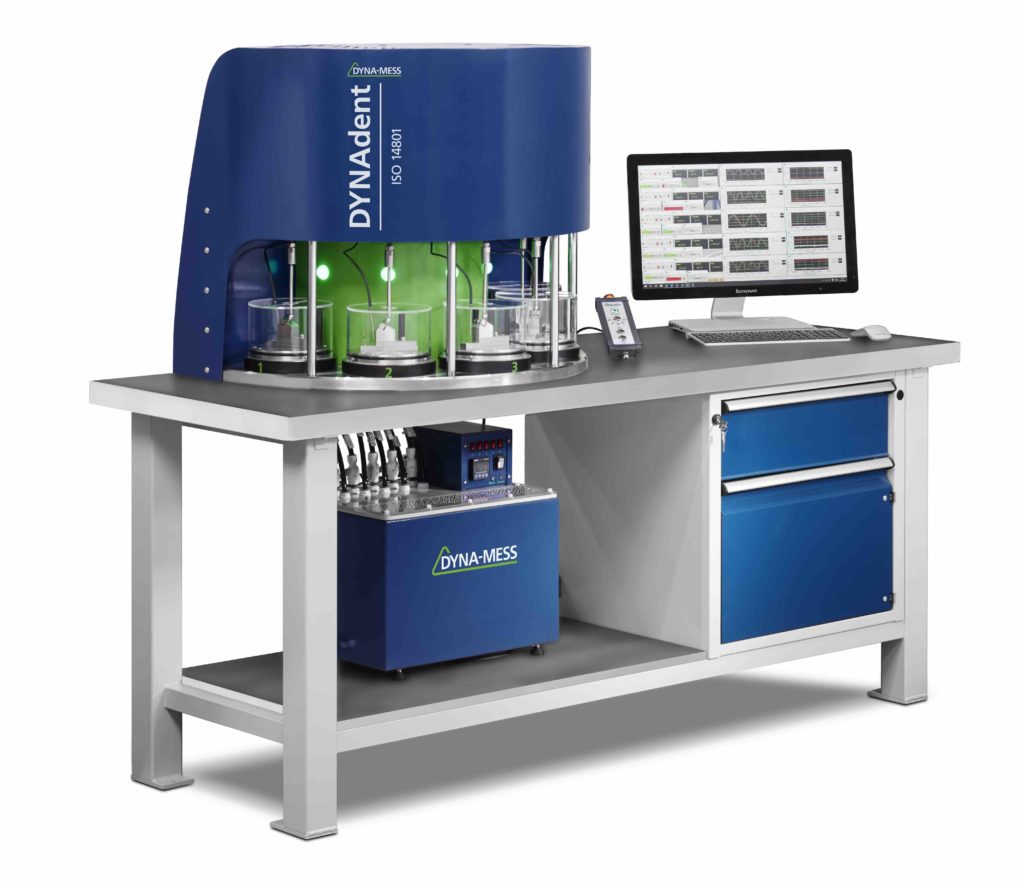

DYNAdent

Testing machine specially adapted to ISO 14801 in two versions: DYNA1dent and DYNA5dent.

- Perfectly adapted for the ISO 14801 fatigue test

- Purely electric drive, which means: no hydraulics, pneumatics or compressed air required

- Force measurement unit integrated in the head of the machine for optimal protection and precise measurement

- Displacement sensor also intergrated in the head of the machine for optimal protection and precise measurement

- Little space required for installation

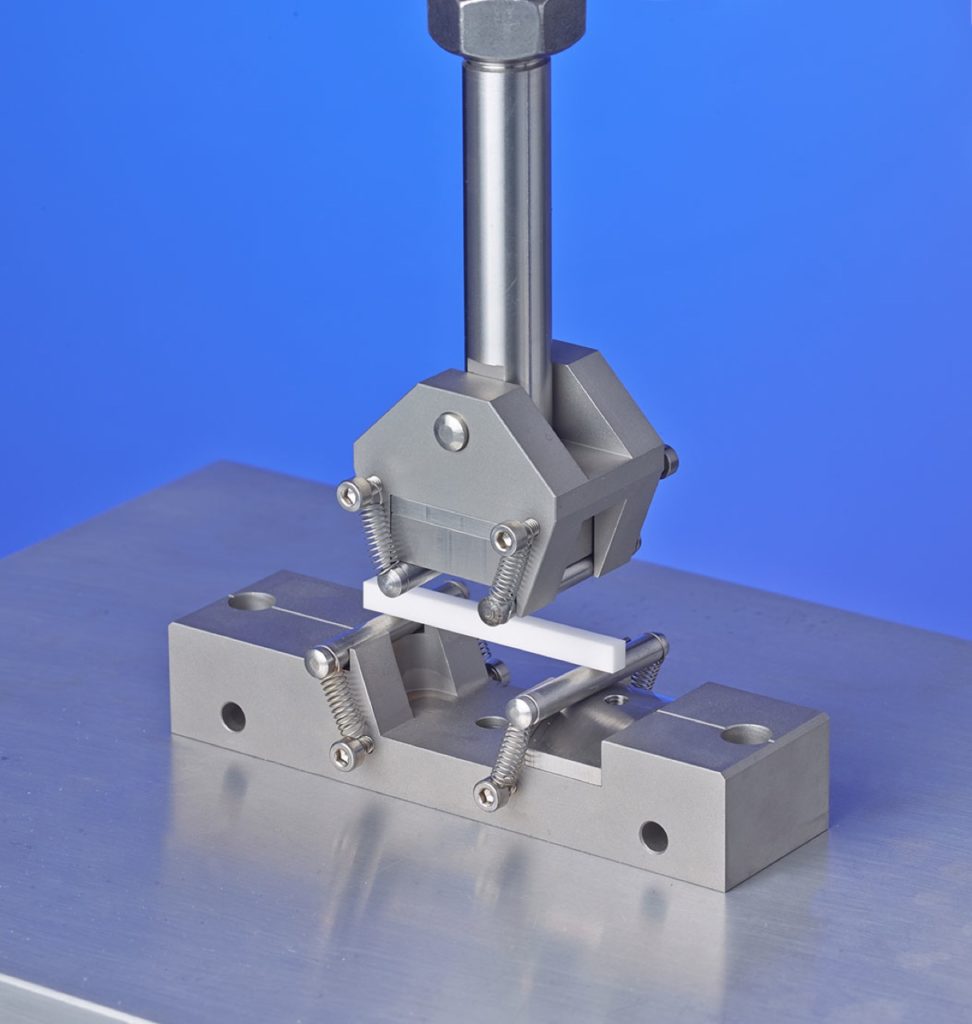

- Simple changing of the test fixture also enables other tests to be carried out, such as 3- or 4-point bending tests or compression tests

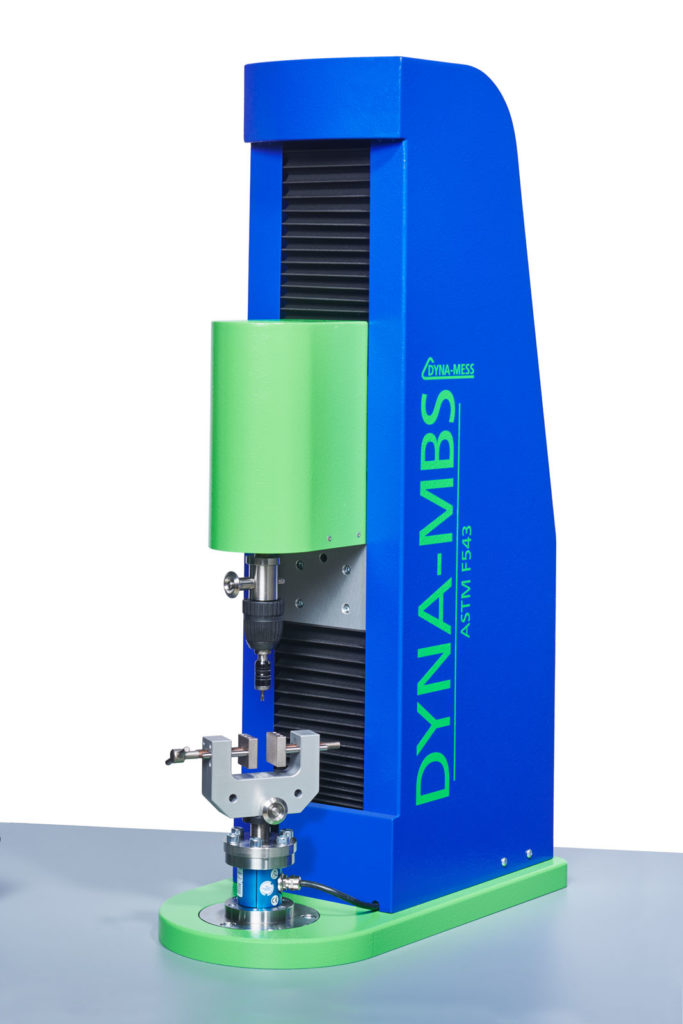

DYNA-MBS: Medical Bone Screw

Special servo-electric testing machine for testing metallic bone screws according to ASTM F543.

Tests according to:

- ASTM F543: Static torsion test

- ASTM F543: Turn in/turn out tests

- ASTM F543: Pull-out tests

- ASTM F543: Self-tapping bone screws

DYNAchew

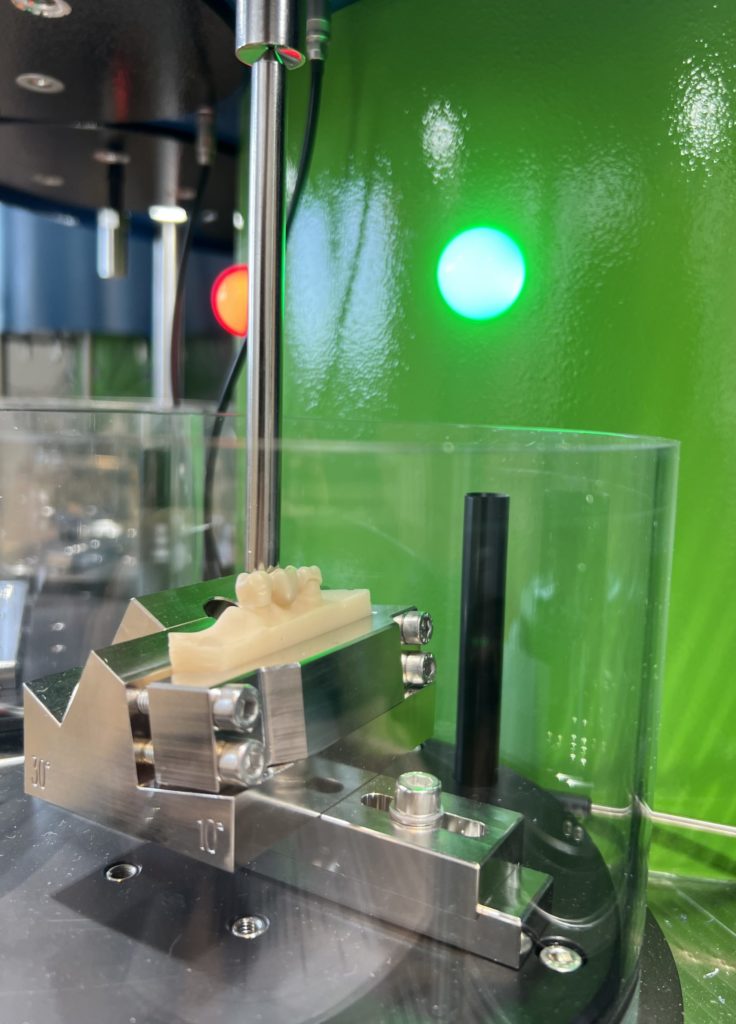

Electrical testing machine with three axes for simulating chewing movements, for testing dental implants in the implant – abutment and abutment – crown arrangement. The tests can be carried out in a temperature-controlled medium.

The software can be used to parameterize the masticatory movements and configure temperature profiles.

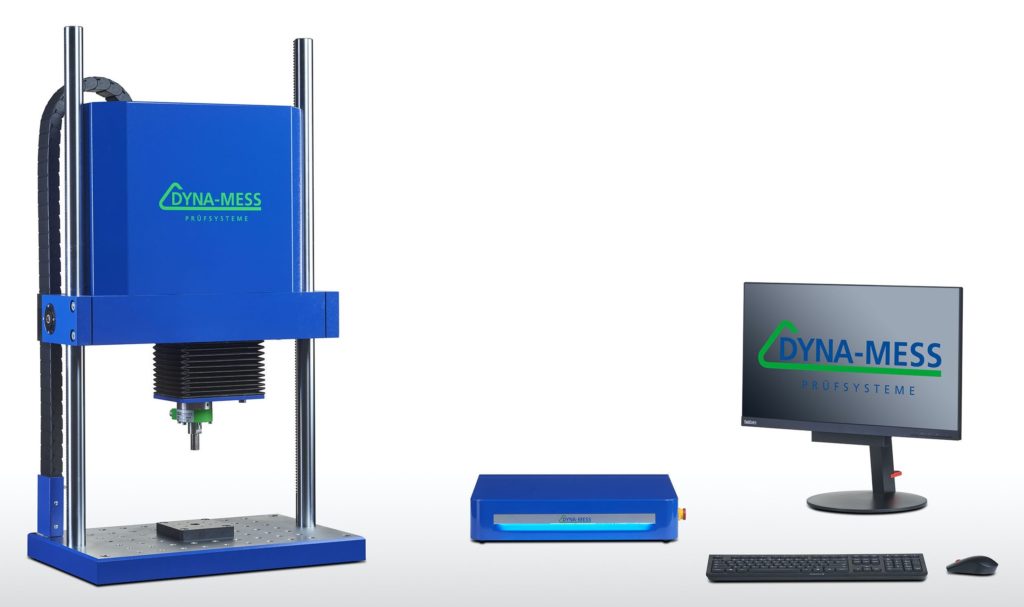

TP 5 HF

A pneumatic universal table-top testing machine that can be adapted to dental testing tasks with the appropriate specimen holders and adapters. Due to forces of up to 5 kN, higher strokes and higher frequencies compared to the DYNAdent, this testing machine can be used for a wide range of tests.

TE 2,5 HCF

An electric universal table-top testing machine that can be adapted to dental testing tasks with the appropriate specimen holders and adapters. Due to forces of up to 2.5 kN, higher strokes and higher frequencies compared to the DYNAdent, this testing machine can be used for a wide range of tests..

Accessories

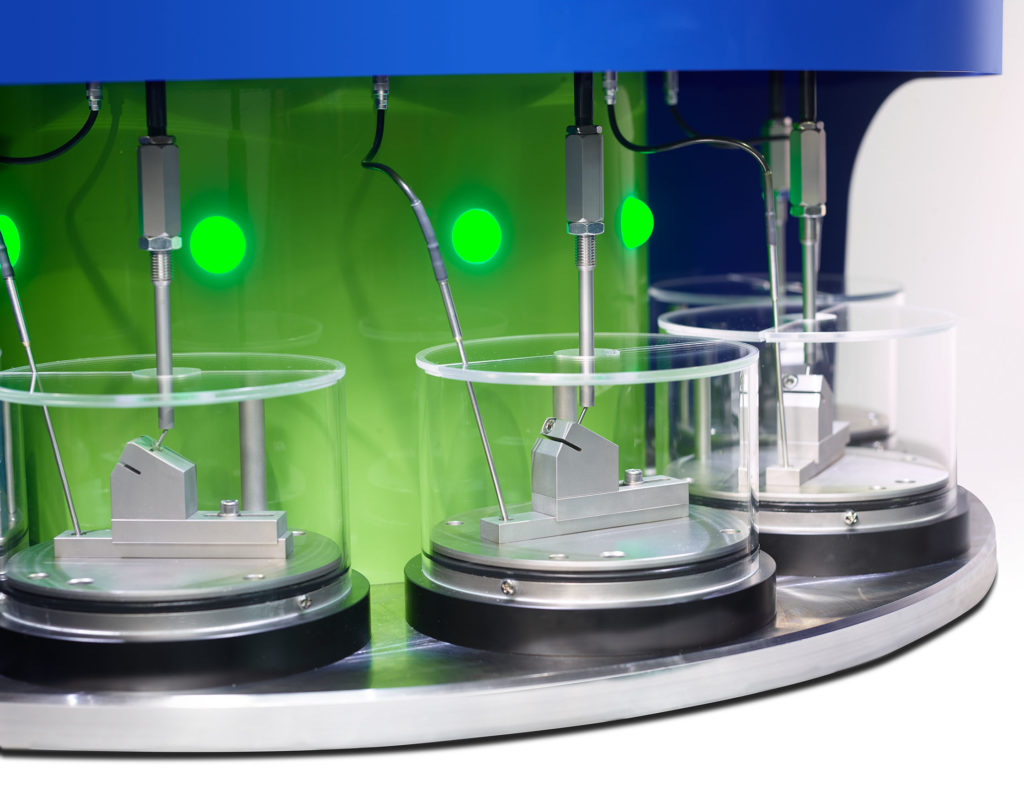

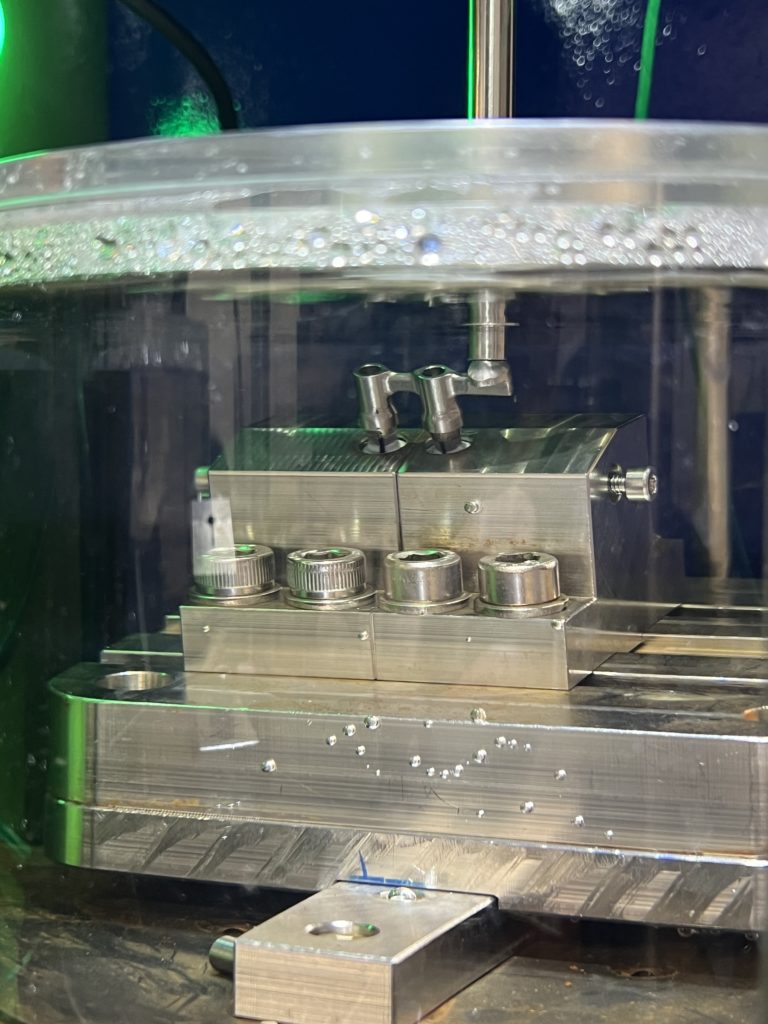

Temperature Unit

The temperature-controlled tempering basin is a basin filled with a liquid medium (water, NaCl…) and is used for standard-compliant simulation (in vitro) under conditions that are as realistic as possible, such as those required for fatigue testing of implants.

A storage tank with 5 circulation pumps and integrated thermostat ensures a continuous circulation of the medium and supplies up to 5 temperature control tanks. The robust and corrosion-resistant design is also ideal for aggressive media such as NaCl.

Specimen holders

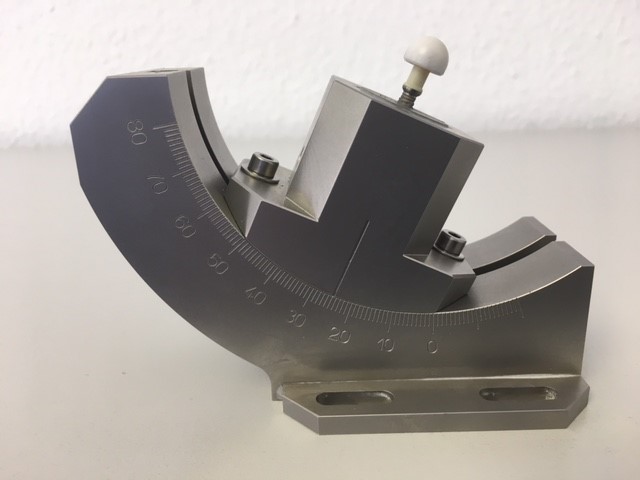

For standard-compliant tests, both appropriate clamping devices and adapters for load application are available, which enable transverse force-free loading of the diagonally clamped implant. In addition, various accessory holders are available to enable further tests (tensile tests, bending tests, etc.).

For example we offer a double sided specimen holder for testing dental and bridge implants, with a clamping angle of 10°.

Device for dynamic fatigue test for endosseos dental implants according to DIN EN ISO 14801

The angle holder offers precise adjustment from 0° to 90° in 1° increments. Its large intake allows for the use of potted samples. A specialized punch enables vertical loading on the semi-ball head of the implant. The holder is also suitable for experiments in liquid media.

Tests

Dynamic fatigue test for endosseous dental implants (DIN EN ISO 14801)

ISO 14801 “Dentistry – Implants – Dynamic fatigue test for endosseous dental implants” describes the test setup, test procedure and test evaluation for single-post endosseous implants. These can be both titanium implants and all-ceramic implants.

Testing of dental materials

Dental materials are tested both on standardized material samples and on finished prostheses. Servo-pneumatic and servo-electric testing machines from DYNA-MESS have been used successfully for this purpose since 1992. Starting from the university research sector, today the leading manufacturers of dental materials and implants also use DYNA-MESS testing machines to determine the fatigue strength of their products.

Dental restorations

A large number of components for dental restorations, such as bridges, are tested on DYNA-MESS test systems.

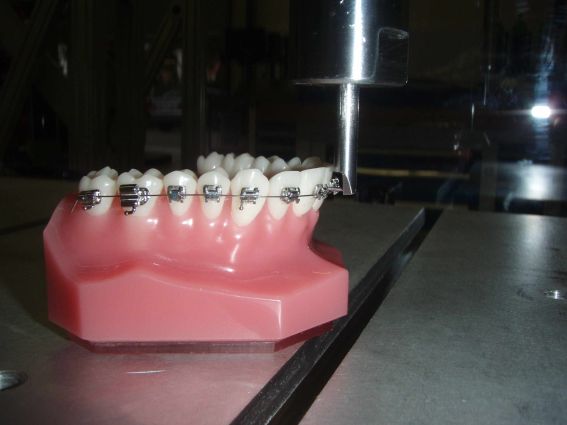

Orthodontic elements

In addition to quasi-static tests to determine the shear strength of fastening elements for orthodontic arches and tensile tests on orthodontic wires, continuous vibration tests can be carried out on “classic” braces, brackets and lingual braces using servo-pneumatic or servo-electric table-top testing machines.